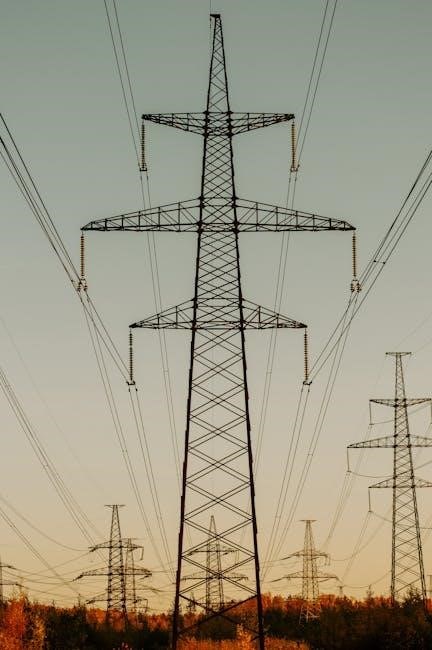

Utility pole guide wires provide structural support and stability to power lines, ensuring safe and reliable energy distribution while withstanding environmental stresses like wind and ice.

1.1 Definition and Purpose

Utility pole guide wires are structural components that provide stability and safety to overhead power lines. Their primary purpose is to protect the lines from environmental stresses like wind and ice, ensuring reliable energy distribution. These wires also act as ground wires, safeguarding the system from power surges and faults, thus maintaining grid integrity and public safety.

1.2 Historical Development

Utility pole guide wires have evolved alongside electrical distribution systems, tracing back to the early 20th century. Initially, they were simple wires for structural support and grounding. Over time, advancements in materials and design improved their durability, with modern guide wires incorporating steel and fiber optics for enhanced safety and reliability in power transmission.

Importance of Guide Wires in Utility Systems

Guide wires are critical for preventing wire sway and damage, reducing risks during storms, and protecting infrastructure and public safety while ensuring reliable power distribution.

2.1 Role in Stability and Safety

Guide wires enhance the structural integrity of utility poles by minimizing wire sway caused by wind or ice, ensuring reliable power distribution and protecting infrastructure from damage. They play a crucial role in maintaining system stability, preventing accidents, and safeguarding public safety by keeping wires securely in place during adverse conditions.

2.2 Contribution to Power Reliability

Guide wires significantly enhance power reliability by maintaining consistent tension on utility lines, reducing the risk of outages caused by environmental factors. They ensure stable connections, minimizing disruptions during storms or extreme weather, and play a key role in delivering uninterrupted electricity to consumers, thereby supporting overall grid performance and customer satisfaction.

Engineering and Design Considerations

Utility pole guide wires are engineered to withstand environmental stresses, requiring precise material selection, load calculations, and tension adjustments to ensure durability and optimal performance.

3.1 Material Selection

Material selection for utility pole guide wires is critical, focusing on durability and resistance to environmental factors. Common materials include high-strength steel and weather-resistant alloys, chosen for their tensile strength and corrosion resistance. Fiber-optic materials are also used for communication lines, ensuring reliable data transmission. Proper material choice balances cost, performance, and longevity, adhering to industry standards for safety and efficiency.

3.2 Tension and Load Calculations

Tension and load calculations are essential for ensuring the structural integrity of utility pole guide wires. These calculations consider factors like wire weight, span length, and environmental stresses. Proper tensioning prevents sagging or snapping, while load calculations account for vertical and horizontal forces. Advanced software tools are often used to optimize these calculations, ensuring safety and reliability under various conditions, including extreme weather events.

Installation and Maintenance

Proper installation ensures guide wires are securely fastened, while regular inspections and testing with tools like multimeters help maintain reliability and safety over time.

4.1 Installation Techniques

Installation involves securing guide wires to utility poles using durable fasteners and ensuring proper alignment. Technicians often test wires with multimeters to confirm voltage and connectivity. Proper grounding techniques are essential to prevent electrical hazards. Regular inspection of wire conditions and connections ensures long-term reliability and safety, minimizing the risk of power disruptions or equipment damage.

4.2 Inspection and Repair

Regular inspections involve checking guide wires for wear, corrosion, and loose connections. Technicians use multimeters to test voltage and ensure proper grounding. Damaged wires are replaced, and connections are tightened to maintain conductivity. Repairs often require power disconnection for safety, ensuring minimal disruption to power distribution while enhancing system reliability and longevity.

Safety Precautions and Handling

Handling guide wires requires proper protective gear and adherence to safety protocols to prevent electrical shocks and physical injuries during installation, maintenance, or repair operations.

5.1 Working with Live Wires

Working with live wires near utility pole guide wires demands extreme caution. Technicians must use insulated tools, wear appropriate PPE, and ensure proper grounding to prevent electrical shocks. De-energizing circuits when possible is crucial for safety. Voltage testers are essential to confirm live wires, while experienced personnel should always supervise such operations to maintain safety standards and compliance with regulations.

5.2 Protective Equipment

Protective equipment is crucial when handling utility pole guide wires. Insulated gloves, hard hats, and safety glasses are essential to prevent injuries. Fire-resistant clothing and steel-toe boots provide additional protection. Voltage testers help identify live wires, while proper grounding tools ensure safety. Adhering to safety standards and using appropriate PPE minimizes risks during maintenance and repair operations.

Types of Guide Wires

Utility pole guide wires are categorized into overhead and underground types, each designed for specific applications and environments to ensure reliable power distribution and communication networks.

6.1 Overhead vs. Underground

Overhead guide wires are mounted on utility poles, providing structural support to power lines and communication cables, whereas underground guide wires are buried, offering protection from weather and accidents. Overhead wires are cost-effective and easier to maintain, while underground wires enhance safety and aesthetics, reducing environmental impact and ensuring reliable service delivery in urban areas.

6.2 Fiber Optic vs. Copper

Fiber optic guide wires offer high-speed data transmission with minimal signal loss, ideal for telecommunications, while copper wires are durable and reliable for power distribution and grounding. Fiber optics are lightweight and resistant to electromagnetic interference, making them suitable for modern utility systems, whereas copper remains a traditional choice for its conductivity and strength in electrical applications.

Applications in Different Industries

Utility pole guide wires are essential in telecommunications for data transmission and in electrical power distribution for reliable energy delivery, ensuring connectivity and safety across various industries.

7.1 Telecommunications

Utility pole guide wires play a crucial role in telecommunications by supporting fiber optic cables and ensuring reliable data transmission. They provide structural integrity, protecting cables from environmental stresses like wind and ice, thus maintaining network stability and enabling seamless communication services across wide areas.

7.2 Electrical Power Distribution

Utility pole guide wires are essential for electrical power distribution, providing structural support to overhead power lines and ensuring reliable energy transmission. They enhance safety by maintaining proper wire tension and preventing contact with other conductors, while also protecting lines from environmental stresses like wind and ice, thus minimizing power outages and ensuring a consistent energy supply.

Role in Power Transmission and Distribution

Utility pole guide wires support power lines, maintaining their position and tension to ensure reliable transmission and distribution of electricity while preventing sagging and contact issues.

8.1 Network Stability

Utility pole guide wires enhance network stability by maintaining consistent tension on power lines, preventing sagging, and reducing the risk of faults during extreme weather conditions like high winds or ice storms.

8.2 Voltage Regulation

Utility pole guide wires contribute to voltage regulation by maintaining proper line geometry, reducing sag, and preventing contact with foreign objects, which helps ensure consistent voltage levels and minimizes power loss during transmission.

Troubleshooting Common Issues

Utility pole guide wires often face issues like corrosion or damage from environmental factors, requiring regular inspection and testing to ensure reliability and safety.

9.1 Identifying Faults

Identifying faults in utility pole guide wires involves testing for voltage using multimeters, checking ground resistance, and inspecting for visible damage or corrosion. Damaged wires may show signs of wear, such as fraying or discoloration, indicating potential failure points. Regular inspections and diagnostic tests are essential to detect issues before they escalate, ensuring system reliability and safety.

9.2 Repair Techniques

Repairing guide wires involves de-energizing the system, inspecting for damage, and replacing faulty segments. Techniques include splicing wires, re-tensioning, and ensuring proper grounding. Protective gear and multimeters are essential for safe and effective repairs. Regular maintenance and inspections help prevent faults, while durable materials ensure long-term reliability and system integrity.

Regulatory Standards and Compliance

Regulatory standards ensure guide wires meet safety and reliability requirements, with guidelines from organizations like IEEE and NEC governing installation, materials, and maintenance practices.

10.1 Industry Regulations

Industry regulations for utility pole guide wires ensure safety and reliability, with standards like IEEE and NEC governing materials, installation, and maintenance. These regulations also address environmental factors and adapt to technological advancements, ensuring compliance with safety protocols and performance requirements.

10.2 Compliance Measures

Compliance measures for utility pole guide wires involve regular inspections, testing, and maintenance to meet industry standards. Documentation and reporting ensure adherence to regulations, while training programs for technicians and engineers maintain high safety and operational standards, preventing potential hazards and ensuring long-term reliability of power distribution systems.

Environmental Impact and Considerations

Utility pole guide wires must be installed to minimize ecological disruption, ensuring erosion prevention and reducing habitat interference, while adhering to environmental regulations for sustainable power distribution.

11.1 Erosion Prevention

Utility pole guide wires are installed with erosion prevention measures, such as proper anchoring and soil stabilization, to prevent ground degradation and ensure long-term structural integrity, reducing the risk of pole instability due to soil erosion caused by weather conditions or water runoff.

11.2 Ecological Impact

Utility pole guide wires can impact local ecosystems by altering landscapes and potentially disrupting wildlife habitats. Proper installation and material selection help minimize ecological damage, ensuring harmony with the environment while maintaining essential infrastructure for power distribution and communication systems.

Advances in Technology

Smart grid integration and material innovations enhance guide wire efficiency, enabling real-time diagnostics and improved reliability in power distribution systems.

12.1 Smart Grid Integration

Smart grid integration enhances utility pole guide wires with real-time monitoring and advanced sensors, enabling predictive maintenance and improved power distribution efficiency. IoT technologies optimize energy flow, reduce outages, and ensure grid stability, while data analytics predict potential failures, boosting overall system reliability and responsiveness to dynamic energy demands.

12.2 Material Innovations

Material innovations in utility pole guide wires include the use of high-strength, lightweight materials like advanced polymers and high-tensile steels. These materials enhance durability, reduce weight, and improve resistance to environmental factors such as corrosion and extreme temperatures, ensuring longer lifespan and reduced maintenance needs for modern utility systems.

Utility pole guide wires are essential for reliable power distribution, ensuring safety and stability. Their evolution and material advancements promise continued efficiency and innovation in utility systems.

13.1 Recap of Key Points

Utility pole guide wires are crucial for stabilizing power lines, ensuring safety and reliability. They withstand environmental stresses, are made from durable materials, and require precise installation and maintenance. Guide wires play a vital role in power distribution, telecommunications, and network stability. Regular inspections and repairs are essential to prevent faults and ensure longevity. Their design and material innovations continue to enhance efficiency and safety in utility systems.

13.2 Future Outlook

The future of utility pole guide wires lies in smart grid integration and sustainable materials. Innovations in design will enhance durability and efficiency, reducing environmental impact. Advanced installation techniques and real-time monitoring systems will improve reliability. These advancements will ensure safer, more resilient power distribution networks, meeting the growing demand for efficient energy solutions globally.